Wire Arc Additive Manufacturing: MX3D

Project By

Joris Laarman Lab, MX3D

Application

Wire Arc Additive Manufacturing (WAAM)

Outcome

Development of an innovative robotic application, realisation of several prototypes which led to the creation of a spin-off company.

Joris Laarman

Joris Laarman, a Dutch designer, explores the intersection of art, design, science, and technology. In 2013, he began experimenting with Wire Arc Additive Manufacturing (WAAM), a robotic metal 3D printing technique. Using HAL Robotics’ CAD-based programming capabilities, the team at Joris Laarman Labs brought this innovative process to life.

The success of their work led to the spin-off of MX3D as an independent entity. MX3D gained recognition for its WAAM bridge over an Amsterdam canal, which was completed in 2021.

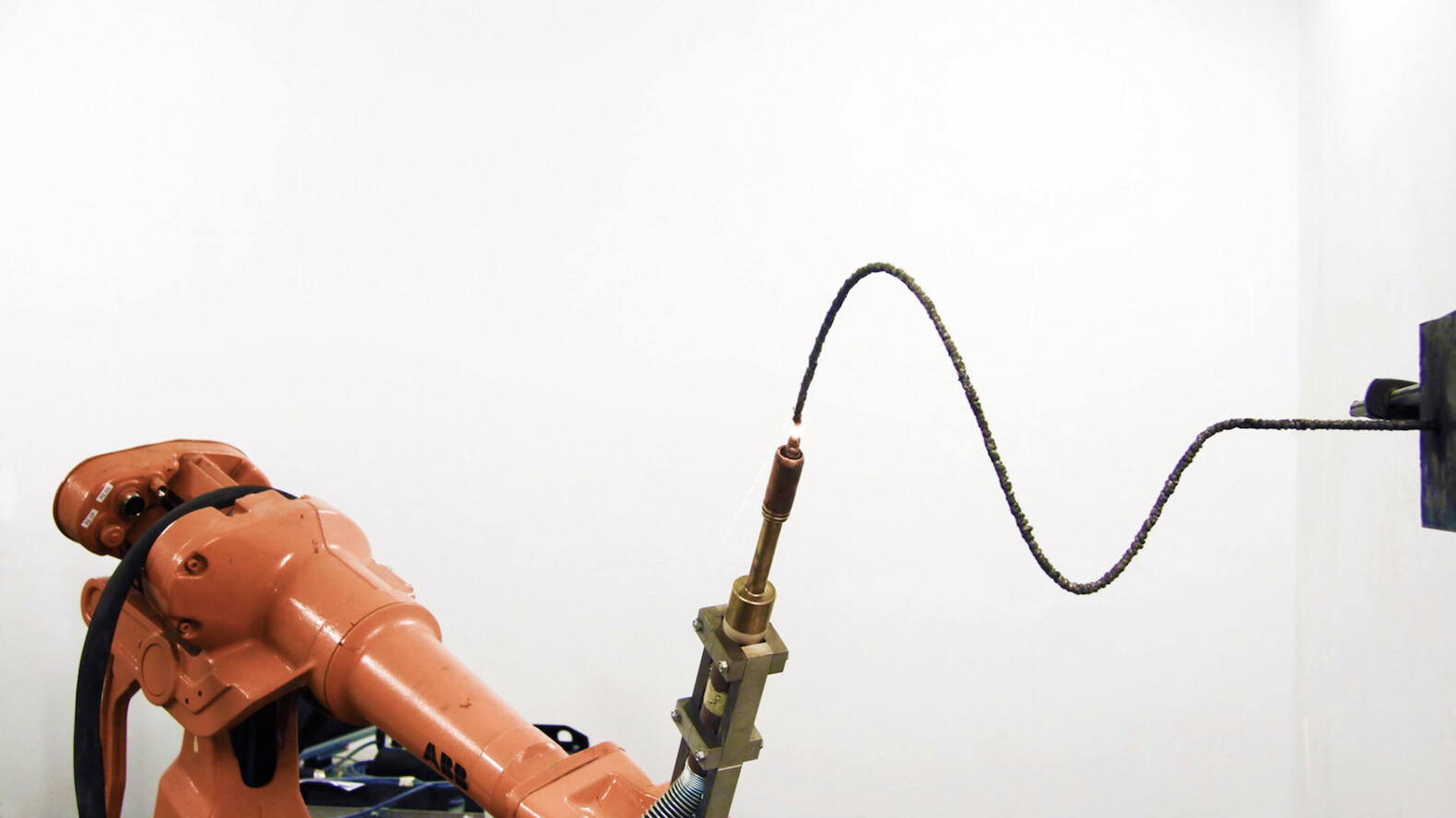

Wire Arc Additive Manufacturing

Wire Arc Additive Manufacturing (WAAM), also known as directed energy deposition-arc (DED-arc), is a production process used for 3D printing or repairing metal parts. WAAM involves depositing layers of metal on top of each other until a desired 3D shape is created. It enables local, on-demand production of products made out of metals such as steel, stainless steel, aluminium, bronze, or copper, reducing inventory and logistics costs.

On the programming side WAAM can be achieved using a traditional robot offline programming workflow:

- The first step is designing the 3D object using computer-aided design (CAD) software. This generates a digital part model.

- The part is sliced into many layers, and a toolpath for the robot arm is created.

- The toolpath is then converted into a machine-readable format for the robot.

In order to experiment with the process during preliminary application research and calibration, it is very beneficial to have all these steps achievable within a single software environment.

HAL Robotics software for robot application prototyping and R&D

Despite employing conventional welding equipment, Wire Arc Additive Manufacturing (WAAM) relies on intricate toolpaths and seamless integration with CAD software to bring these elegant structures to life. Manually programming a robot to produce such shapes would be an insurmountable challenge. HAL for Rhino/Grasshopper was used to automatically convert 3D geometry into robot trajectories, enabling Joris Laarman’s team to iterate very quickly, explore process capabilities, and identify the best settings for producing demonstrators.

The achievements of MX3D underscore the critical role that HAL Robotics software plays for inventors and R&D teams working on advancing novel manufacturing methods.

To learn more about our the HAL Robotics software utilities for robot application prototyping and additive manufacturing processes, please feel free to contact us.