Concrete 3D Printer: Tarmac

Partners

Tarmac, Skanska, ABB, MTC, Loughborough University, Foster + Partners, BRE

Application

Concrete 3D Printing (3DCP)

Outcome

3DCP slicer adapted to robot constraints

Tarmac

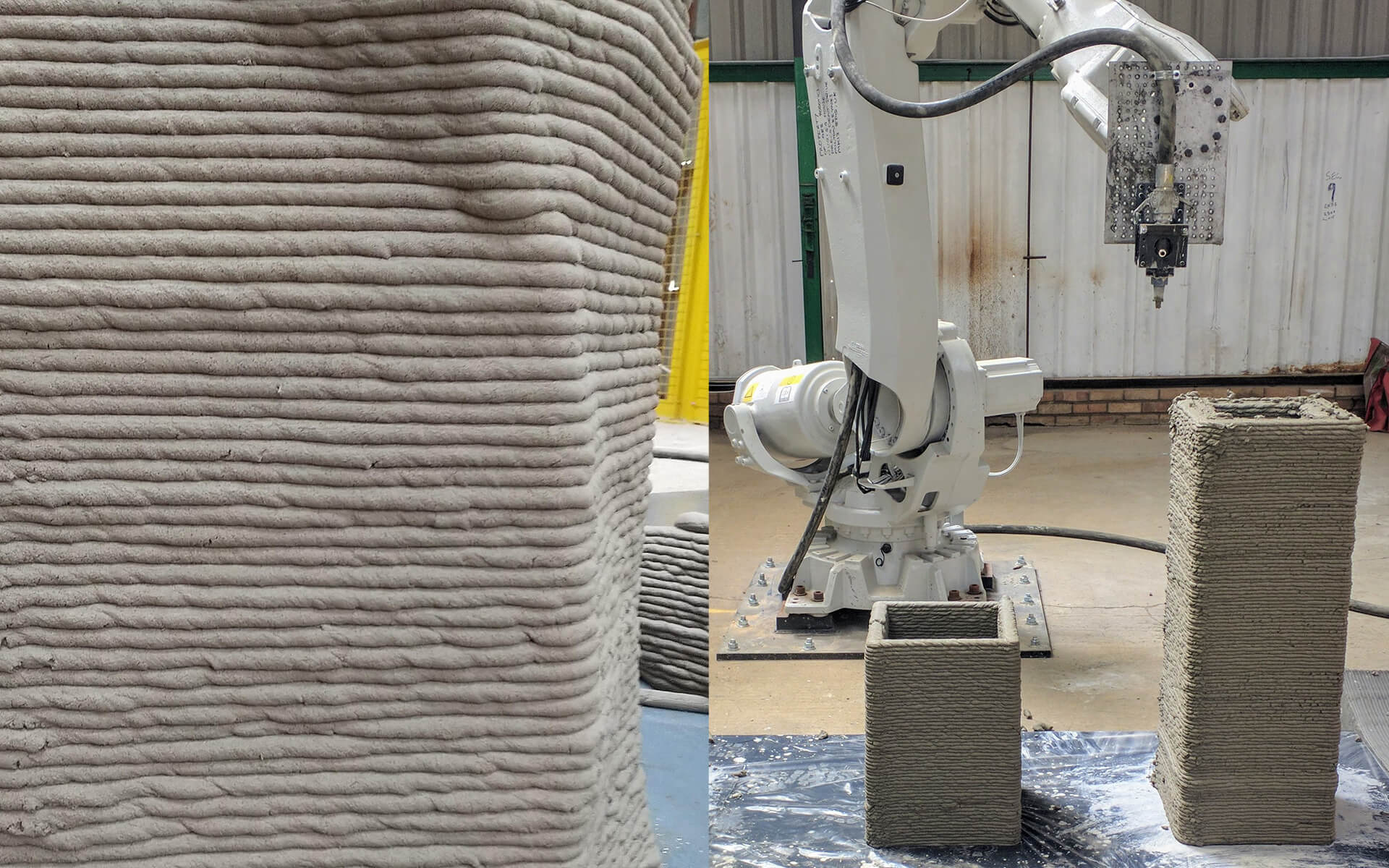

Tarmac is a British building materials company, specialising in cement, concrete and aggregates for the construction industry. The CAMBER project, in collaboration with Skanska, ABB Robotics UK, the Manufacturing Technology Centre, Loughborough University, Foster + Partners architects, and BRE, sought to help Tarmac industrialise Concrete 3D Printing (3DCP). An experimental concrete 3D printer was built during this project, which required to be controlled by concrete specialists with no prior knowledge of robotics.

Concrete 3D Printing: an innovative process

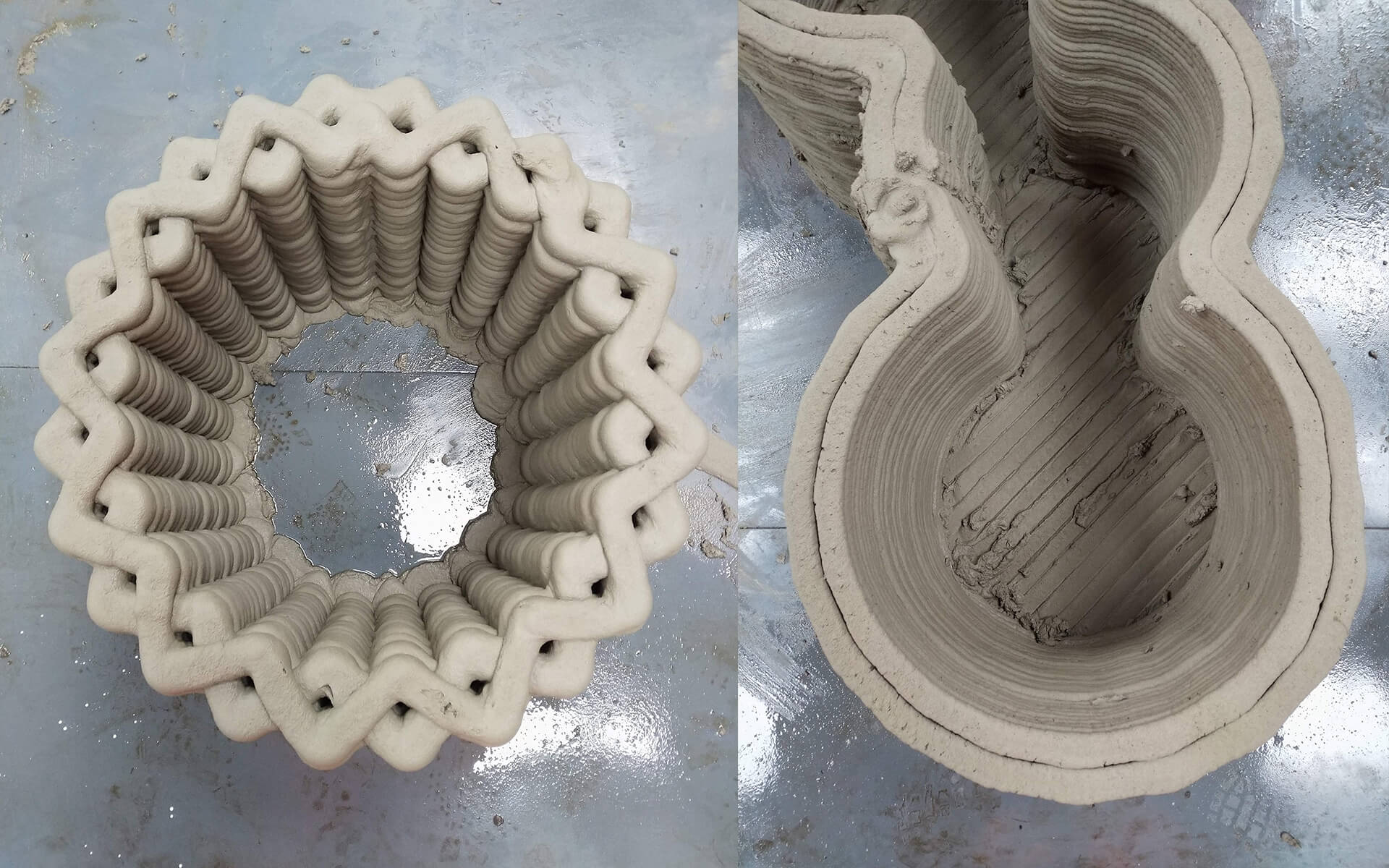

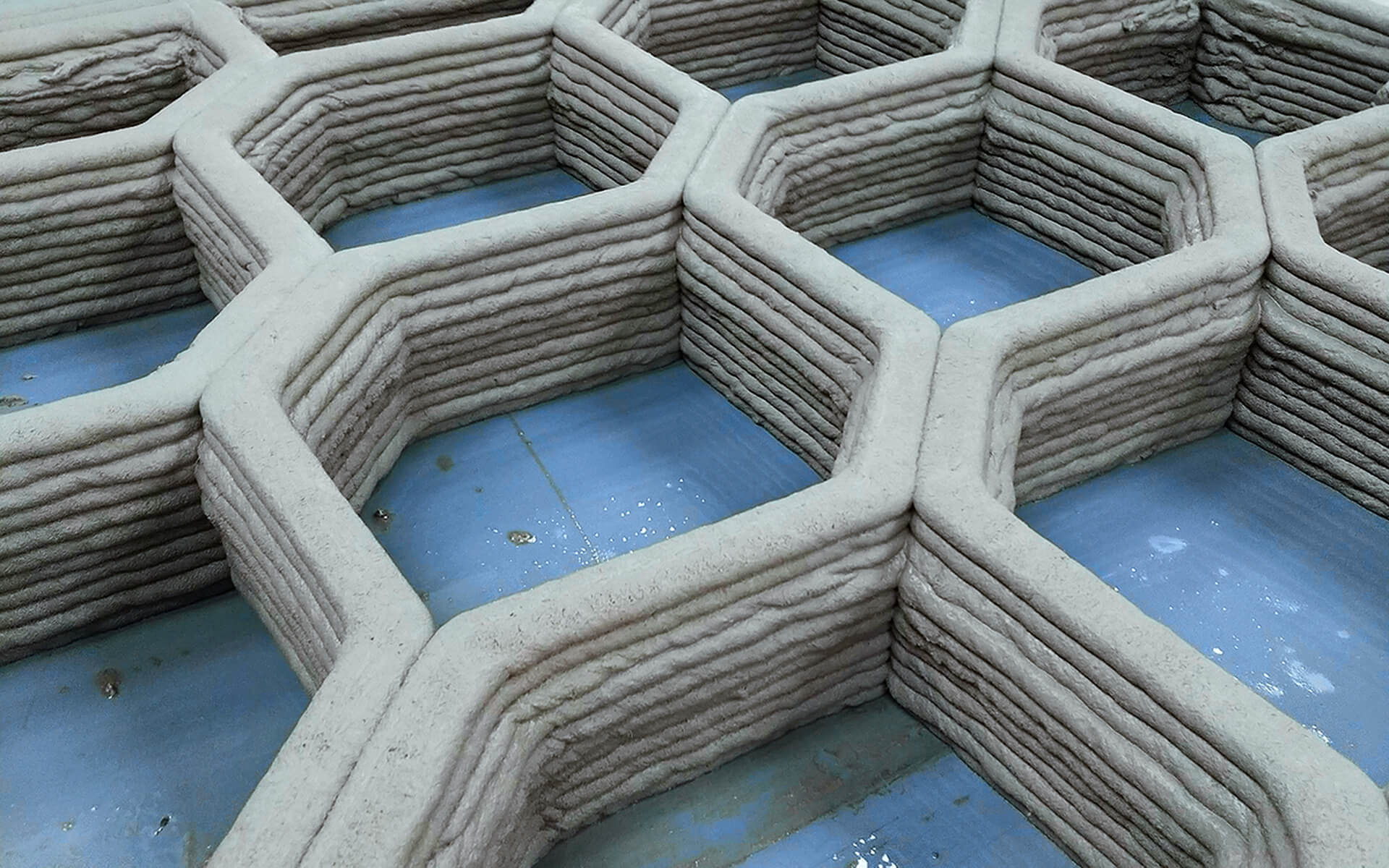

Concrete, widely used in construction, has a significant environmental impact due to its resource-intensive production process and carbon emissions. However, concrete 3d printing offers a promising solution by minimising concrete usage. By precisely depositing material only where it is needed in a component, 3DCP reduces waste, lowers energy consumption, and decreases greenhouse gas emissions. This innovative technology contributes to more sustainable and eco-friendly construction practices.

An easy-to-use operator interface for their concrete 3D printer

HAL Robotics was responsible for creating a user-friendly software interface that simplified programming for the printing robot. This allowed Tarmac’s operators to directly control the concrete 3D printer.

As a materials and pre-cast company, Tarmac’s engineers and operators know their concrete inside and out. However, they are not, and don’t want to be, robotics experts. To address this, we developed a customised user interface that operates on two levels.

- “Simple” Mode: This mode allows operators to make quick adjustments to their printing process based on environmental factors such as temperature and humidity. These changes can be made immediately before producing a part. The interface is designed to be embedded into a portable version of the concrete 3D printer, enabling on-site part manufacturing.

- “Advanced” Mode: Intended for engineers, this mode provides fine-grained control over the printing process and slicing. Engineers can load their parts, choose slice orientations, infill patterns, and other parameters. The result is a parametric procedure for the concrete 3D printer, complete with metadata to ensure valid execution on the actual machine.

The resulting software interface allowed the Tarmac teams to quickly iterate during their process development stages, rapidly gaining experience that helped them identify how Tarmac products could be best used by concrete 3D printers.

To learn more about our bespoke software development services, software modules for 3D Concrete Printing and other additive manufacturing processes, please feel free to contact us.