ROBOTS

THAT ADAPT

TO CHANGE

Automate the processing of variable products, with robots that constantly adapt to part or task changes.

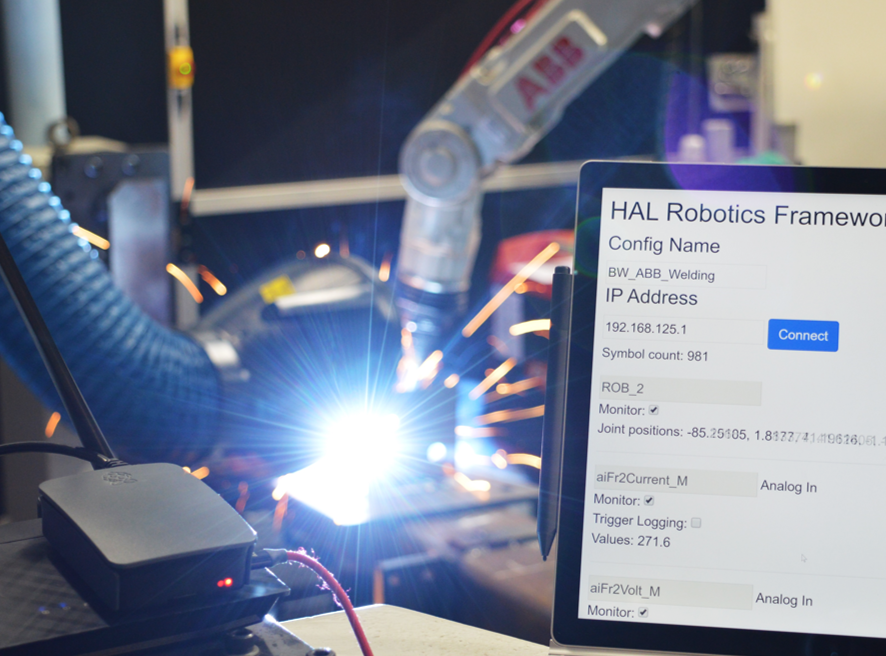

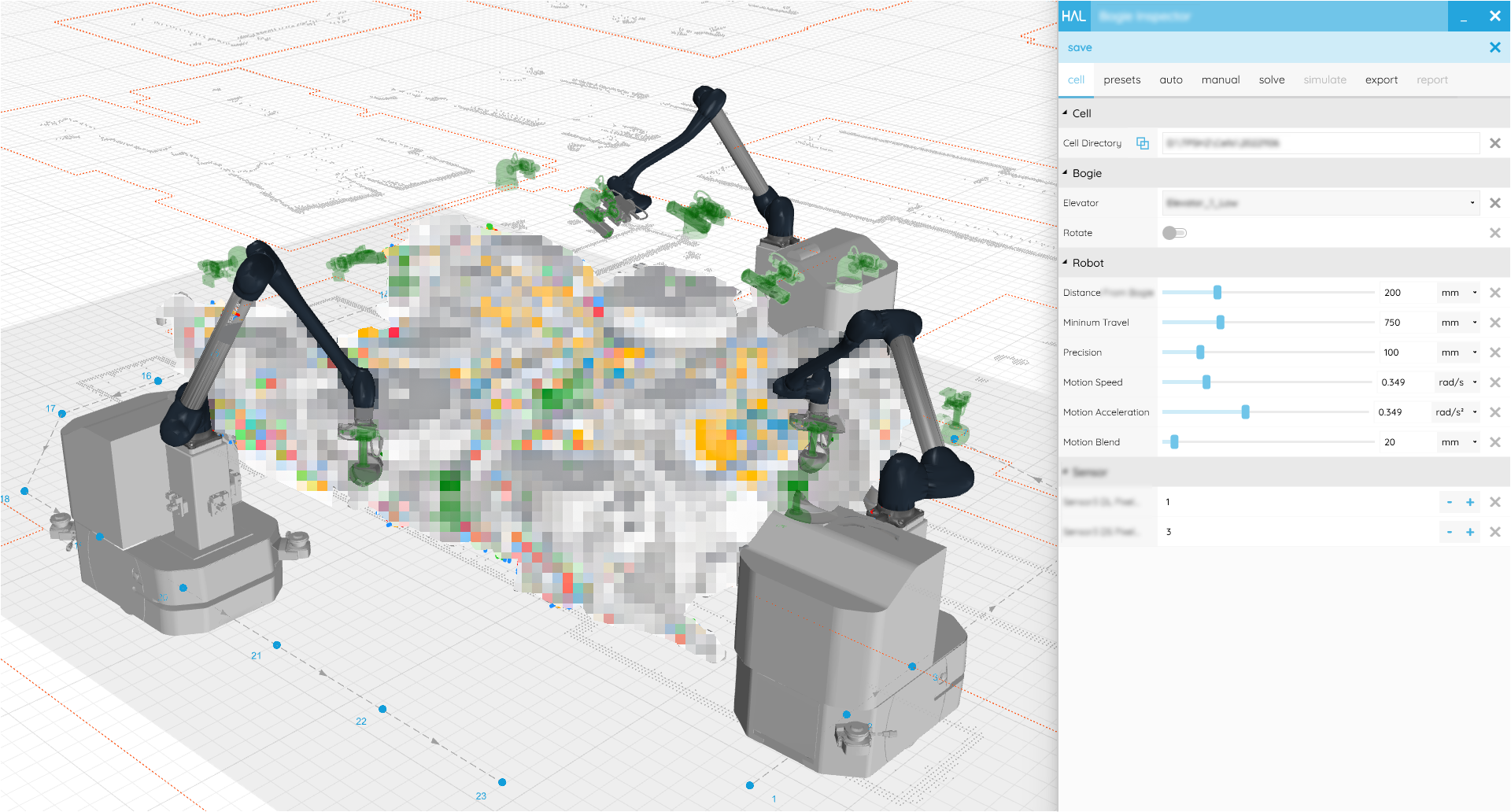

Designed to safely reprogram industrial robots from CAD models, sensor measurements or any other data source, the HAL Robotics Framework enables automation of high-mix, high-complexity tasks.

truly flexible manufacturing

variation is the new standard

Whether you’re automating manual tasks, or starting to offer more product customisation and specialisation to your clients, having production equipment which adapts to variability is critical.

From contract manufacturing aerospace components, to sanding made-to-order cabinets, or engraving musical instruments with a customer’s name, production flexibility is a necessity.

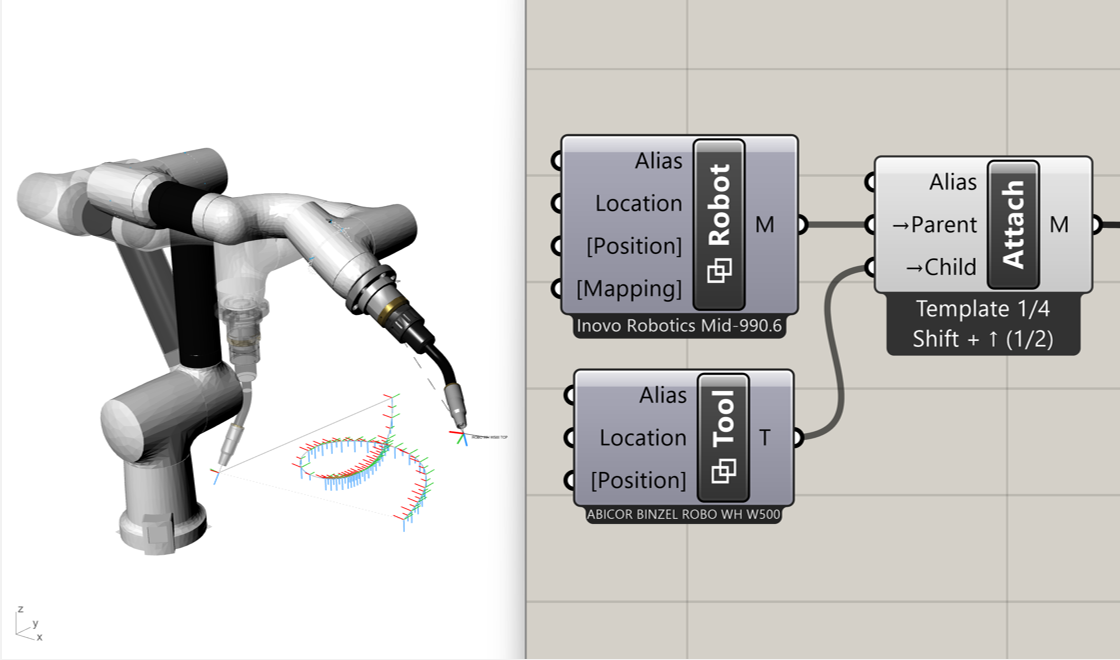

By interpreting data to generate robot instructions rather than using manual, offline, or teach-and-repeat programming, the HAL Robotics Framework is built from the ground up to handle product and process variation.

safe, predictable execution

from error-checked generated procedures to native robot code

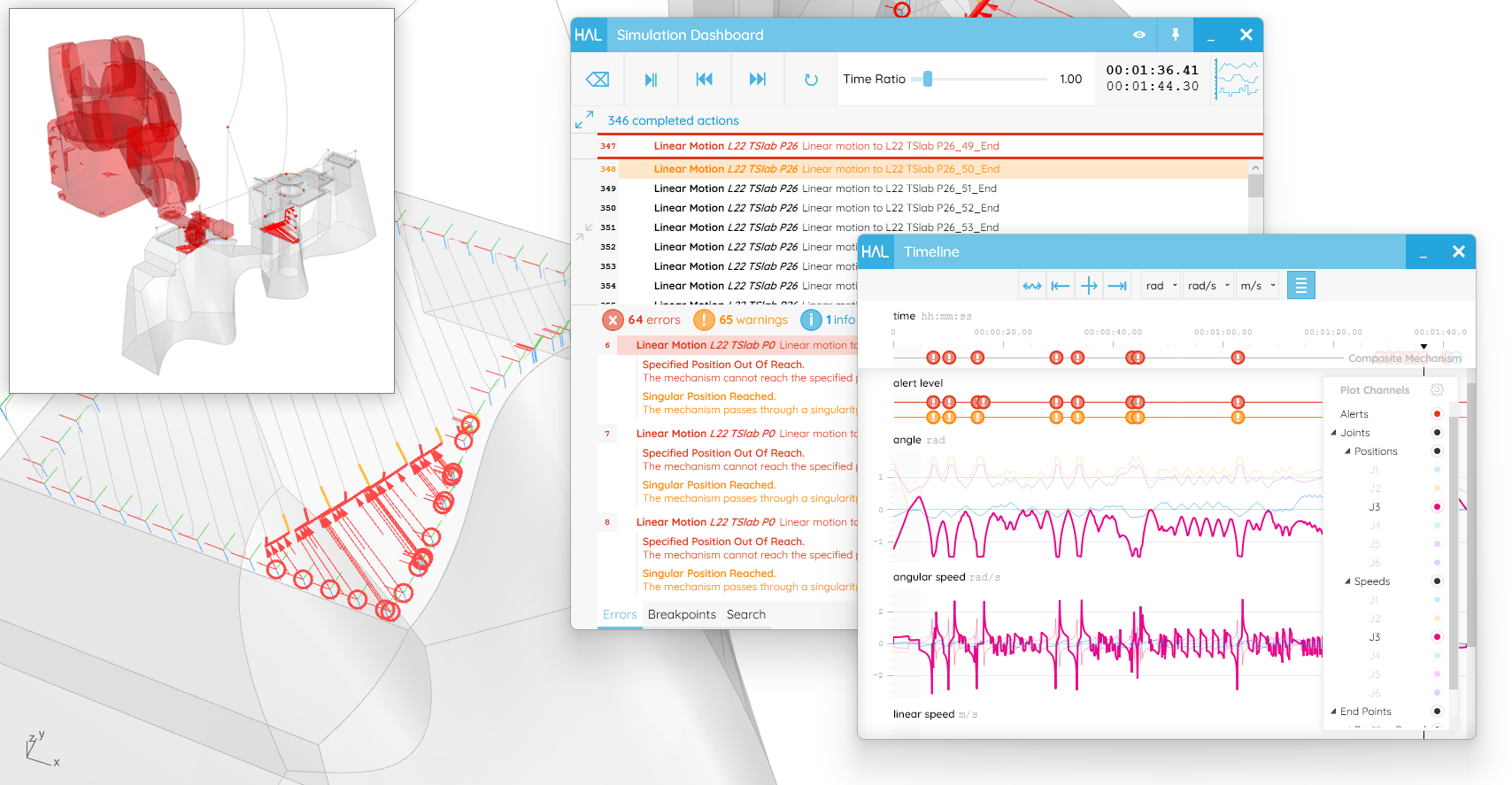

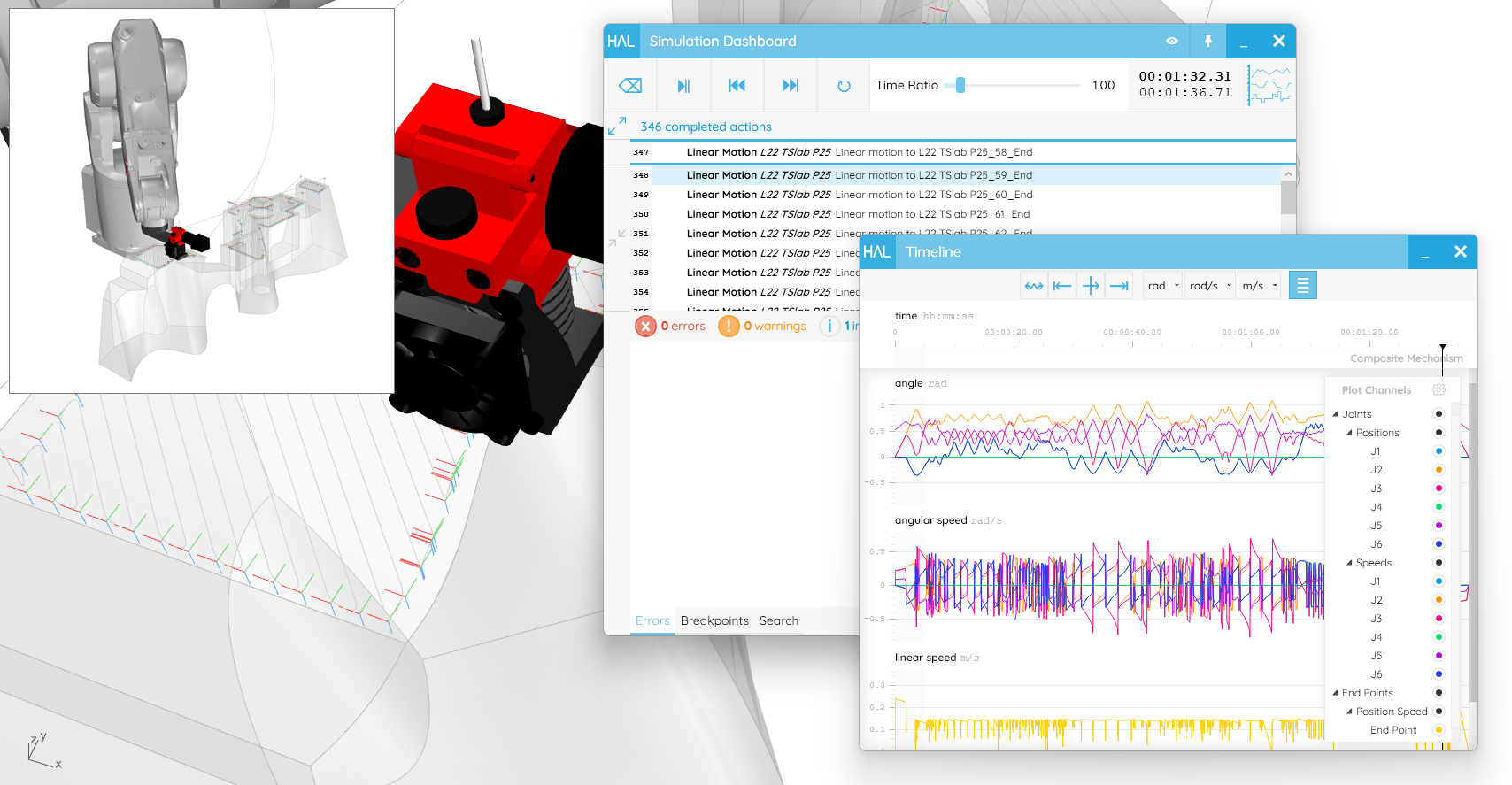

When a robot’s job is changing frequently, you need complete confidence that it’s always going to work safely and without errors.

The HAL Robotics Framework uses a digital twin to simulate and validate procedures before the robot starts. This can run automatically or with human supervision, and uses measured data to ensure the most accurate model possible.

Validated procedures are translated to native robot code to retain all the functionality of your certified safety systems.

the right tool for the job

deployed however and wherever you need it

The HAL Robotics Framework is both portable and highly customisable, meaning it can take exactly the form you need it to. That gives you access to the same powerful robotics software through a tailored user interface for operators to reconfigure a cell, or a micro-service application running autonomously in an embedded system.

always compatible

program any robots, for any processes, on any parts

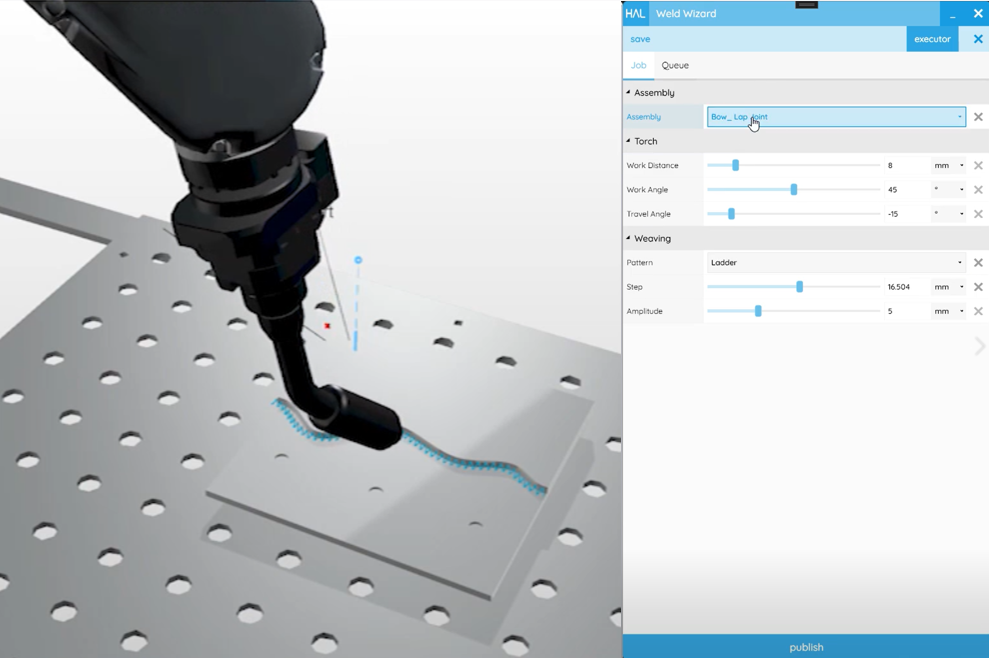

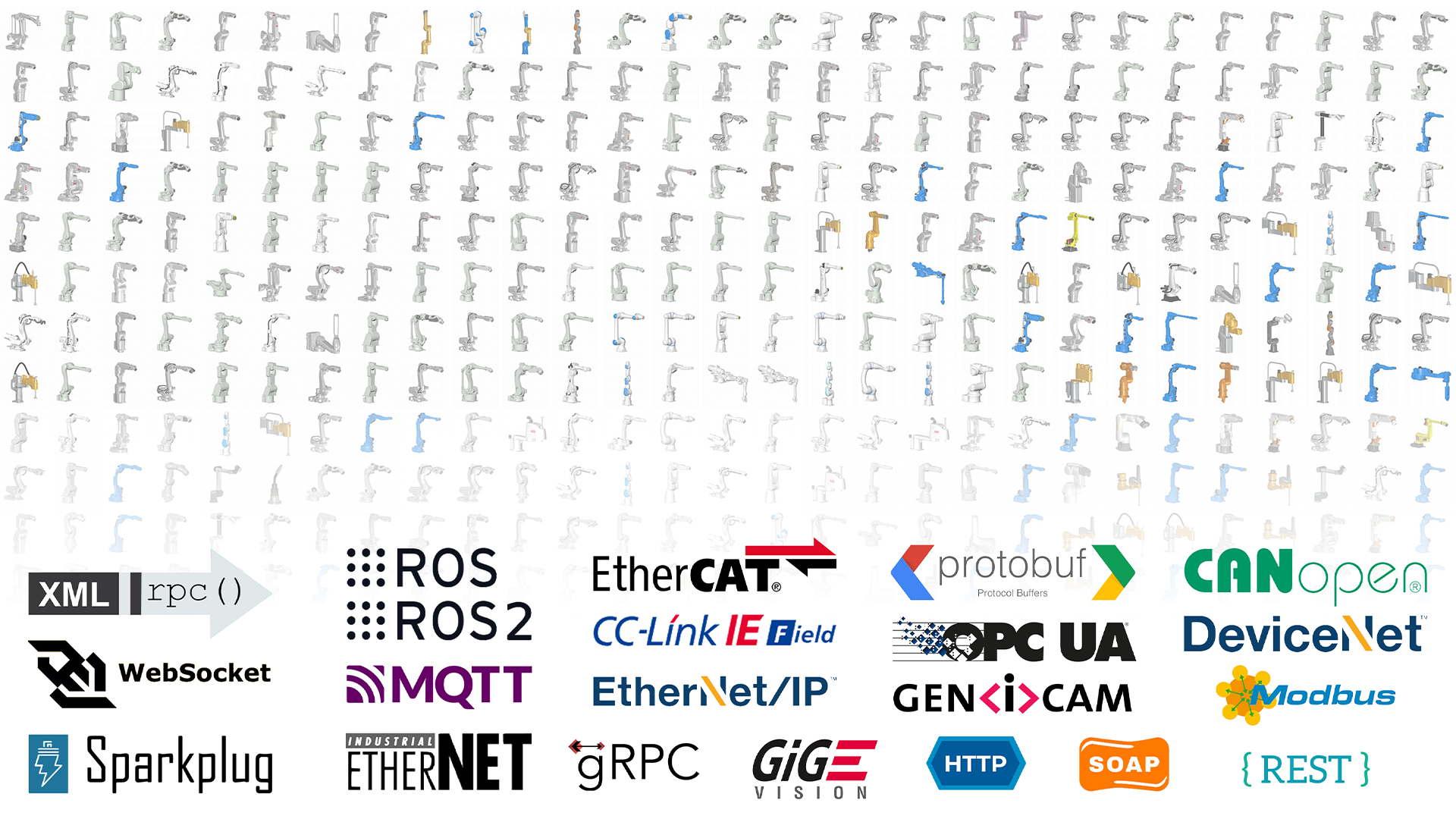

Whether a robot is welding, cutting, or 3D printing, a HAL Robotics Framework procedure ensures that the robot is in the right place at the right time with the right settings.

Every procedure is vendor-agnostic, so it can be exported to any of the hundreds of supported robots and positioners. The Framework can also simulate multi-robot cells and combinations of robots, regardless of their brand or size. Ever wanted to use a Universal Robot on an Omron AGV, or mount an ABB cobot on the end of a KUKA? Now you can.