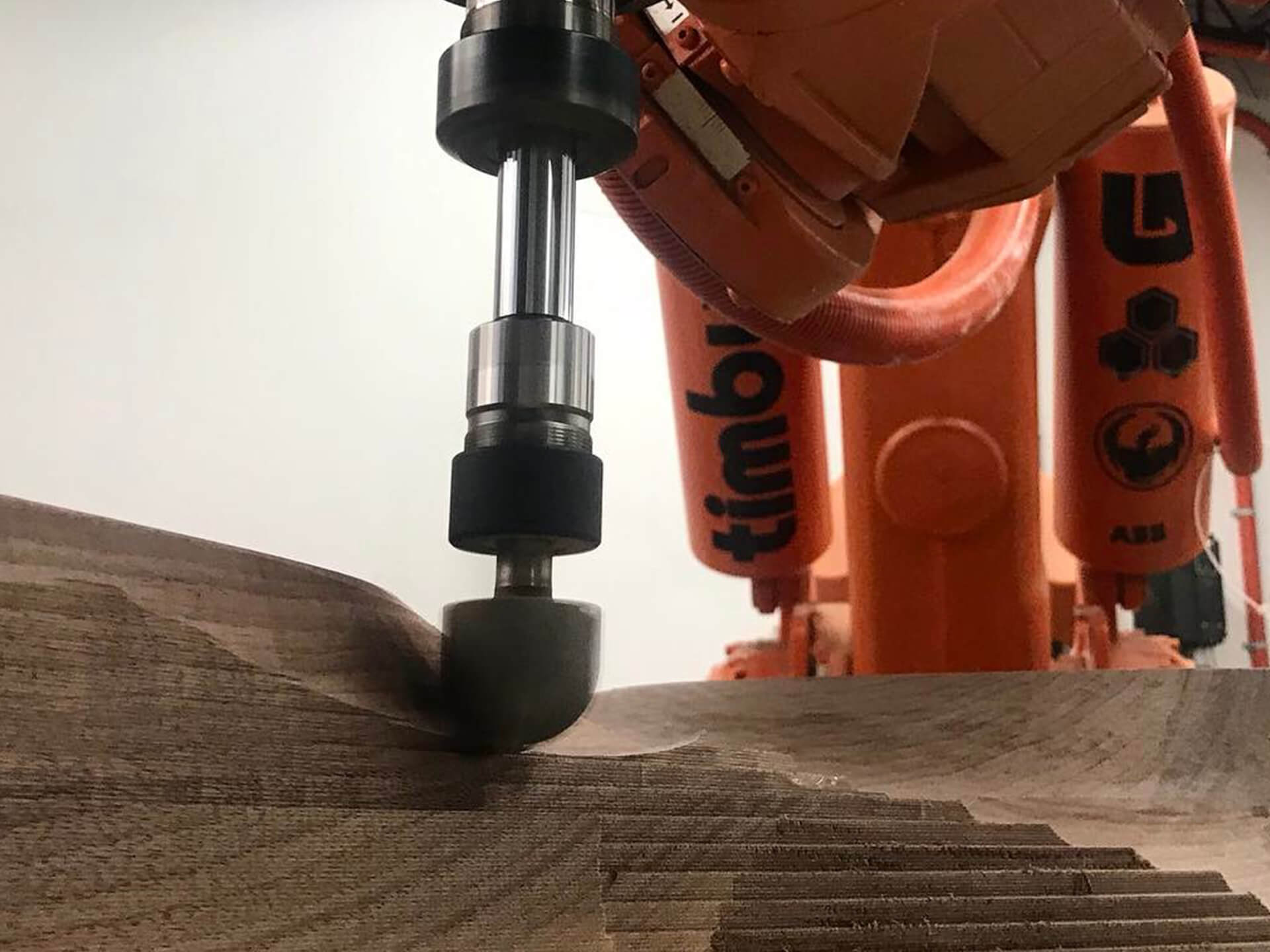

Robotic Machining: Timbur

Project By

Timbur

Application

Timber machining

Outcome

Furniture & Interior design products manufacturing from CAD

Timbur LLC

Timbur is a digital fabrication company that employs advanced robotic and CNC manufacturing techniques to produce distinctive projects for global brands, major retailers, and the architecture, art, and design sectors. Timbur explores the intersection of design, materiality, and robotics to reimagine the natural world. Their works vary in scale from individual furniture pieces to doors, stairs and entire atria.

With a team trained in both computational design and woodworking, Timbur’s team is highly proficient at using a number of software modeling and fabrication tools, with McNeel Rhino/Grasshopper playing a pivotal role as a very flexible modeling and visual programming environment.

7-axis robotic machining

While industrial robots are less rigid and precise compared to gantry-type machines, they provide a cost-effective and space-efficient alternative to CNC machining centers for producing large parts from materials like wood, polystyrene, plastics, and metals.

Timbur’s focus on unique parts and finely detailed geometry makes their robotic processes deceptively challenging. They therefore leverage HAL Robotics’ technology to simplify the programming of their 7-axis robotic machining cell. This enables them to produce large scale complex forms that are often not achievable with traditional 3 and 5-axis machining technology.

HAL Robotics software for multi-axis robotic machining

Machining typically involves very long and complex toolpaths to iteratively remove material from an initial stock piece. Multiple toolpath strategies are usually generated and combined using specialized CAM software, creating multiple geometric patterns on the part, which are then followed by the cutting tool mounted on the robot.

Timbur employs a mix of commercial CAM software and custom toolpath generators that they’ve programmed themselves. This approach allows them to efficiently manufacture large-scale objects. HAL Robotics’ software plays a crucial role in this process:

- Feasibility Validation: It assesses the feasibility of these toolpaths using a 7-axis robotic machining cell. This helps prevent issues that could slow down or halt these lengthy tasks.

- Motion Conversion: The resulting millions of robot motions are converted into instructions compatible with the cell controller.

Customised CAM Services: G-Code Conversion and Toolpath Programming

- G-Code Conversion: If your robotic cell or process needs to convert existing G-Code—say, to use 3-axis CNC software alongside your robot—HAL Robotics’ software can assist in converting these programs for robotic machining.

- Tailored Toolpath Programming: Alternatively, if your machining process requires a specific toolpath strategy, our development team specializes in both computational geometry and robot control. We’ll work closely to find the optimal solution for your application.

To learn more about our software modules for robotic machining, G-Code conversion and robot simulation, please feel free to contact us.