Welding Robot Monitoring

Client

Bryden Wood

Partners

ABB

Application

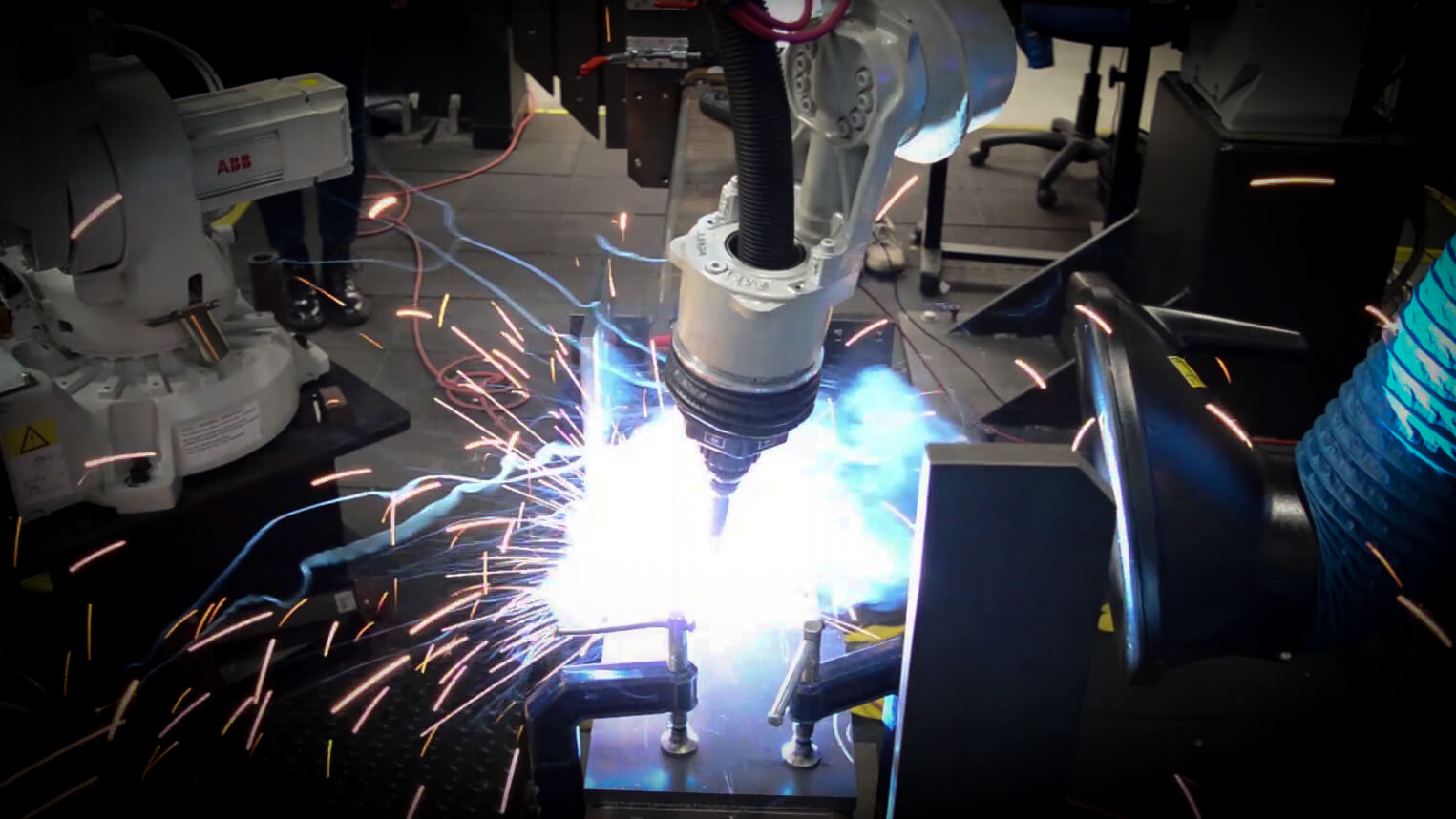

Welding

Outcome

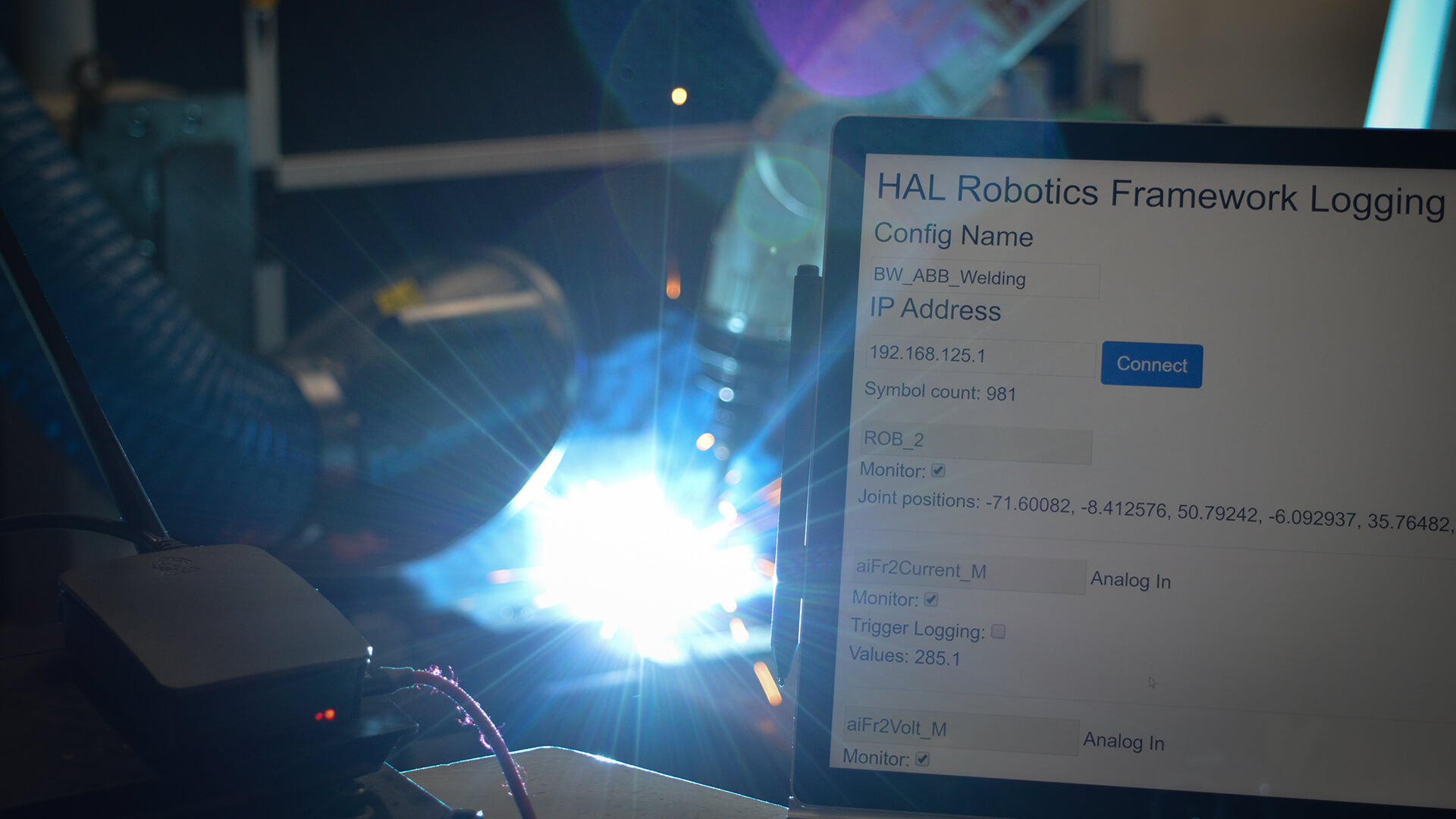

Monitoring and logging of robotic welding process events on low-cost edge hardware

Bryden Wood

Bryden Wood is a multi-disciplinary company of creative technologists, designers, architects, engineers and analysts working in AEC. As part of their focus on Modern Methods of Construction (MMC) and Design for Manufacture and Assembly (DfMA) they are exploring the automated fabrication of a kit-of-parts for construction known as “Platforms”.

Having previously used the HAL Robotics software for their initial research and development into manufacturing critical bracketry for this system, they turned to HAL Robotics to assist with trials, extracting real-time data from the process from a welding robot.

Welding robot monitoring

To enable this, we developed a lightweight application to communicate with an ABB IRC5 robot controller and monitor:

- I/O signal states,

- welding robot joint positions,

- welding torch positions,

- welding power source current and voltage

This data was stored locally and streamed to a database for later analysis. To test the efficiency of the application, it was successfully run on a Raspberry Pi.

This kind of data can be critical for identifying any issues that may have arisen during production using such a welding robot. For example, should there be any spatter during the welding process, we can investigate whether there were any variations in process parameters at that moment. If so, we can extrapolate this information and identify this type of defect during runtime, and adapt the process accordingly by changing either the tooling or robot parameters. This is a critical step in creating robust, self-correcting processes with increased productivity and reduced rework.

The HAL Robotics software, on the Edge (embedded)

We developed the HAL Robotics Framework to be deployed on a variety of systems, making it the perfect software ecosystem for distributed robot programming, simulation and monitoring.

Acting as a unifying middleware between robots, sensors, end-effectors and the customer’s specific software environement, tour software eliminates data conversion issues. It servers as the ideal software “glue”, bringing together a variety of industrial automation technologies, without the need to manuallty deal with different communication protocols.

Bryden Wood benefited from our custom software development services to access low-level robotic welding process data, allowing their R&D department to add a new stream of information to their data-driven design practice.

To learn more about our robot software development services, welding robots, or software modules for monitoring and robot controller expansion, please feel free to contact us.